What is the purpose of edgewise winding?

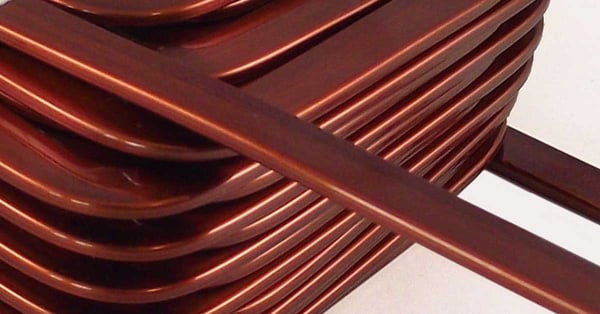

Edgewise winding is one of the modern trends in coil manufacturing. The principle of this winding technology is that the rectangular section wire is wound not on the flat part of the wire but on the short side of the wire. That’s where the terms edgewise winding or side-winding stands for.

Edgewise wound coils are typically used in power electronics and motors, especially where the building volume, thermal properties and/or electrical losses are critical parameters. There are some advantages and disadvantages to consider. Edgewise windings are available for air core coils, but can also be applied for bobbin coils, depending on the customer’s requirements. These coils can be produced in a wide variety of shapes.

KUK Coils has a great deal of experience in coil manufacturing with edgewise windings. Our product team is happy to offer any advice for your development projects!