Selecting conductor materials for axial and radial flux motors

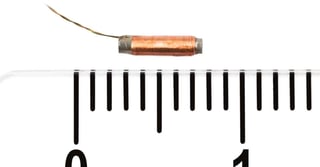

Conductor material choice significantly influences efficiency, cost, and thermal performance in both axial and radial flux motors, with options like copper, aluminum, or alloys needing to align with flux paths and power density requirements. Axial flux designs often prioritize lightweight materials to leverage their compact form, while radial flux benefits from high-conductivity options for ...