How to select a strategic coil manufacturer for automotive Tier 1 or 2 suppliers

The automotive industry is undergoing a profound transformation driven by the rise of e-mobility and evolving customer expectations for comfort and entertainment. As automakers strive to deliver innovative and high-performance vehicles, contract manufacturers play a pivotal role in supporting their supply chains.

When it comes to identifying a strategic manufacturing partner, engineers and purchasers of Tier 1 or 2 suppliers face a daunting task. They must navigate through various conditions that are crucial in coil winding for the automotive industry.

1. Expertise in drive and comfort systems

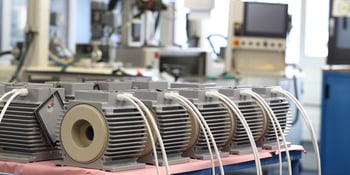

A contract manufacturer should possess a deep understanding of the electronic components used in both drive and comfort systems, including stepper motors, solenoids, and sensors. They should have experience designing, developing, and manufacturing these components to meet the specific requirements of automotive applications.

2. Internal automation know-how

The ability to rapidly and flexibly ramp up production is crucial for automotive OEMs and Tier 1 or 2 suppliers. A contract manufacturer should have internal automation expertise to streamline manufacturing processes and adapt quickly to changing demand.

3. Robust quality assurance

Quality is paramount in the automotive industry. A contract manufacturer should adhere to stringent quality standards, such as IATF 16949 certification, to ensure that every component meets or exceeds customer expectations.

4. Capacity to handle diverse volumes

Automotive manufacturers operate on a global scale, requiring contract manufacturers with the capacity to handle a wide range of production volumes, from 1 million to 100 million pieces per year.

5. Strong communication and collaboration

A successful partnership between an automotive supplier and a contract manufacturer requires open and effective communication. The contract manufacturer should be willing to collaborate closely with the supplier throughout the product development and manufacturing process.

6. Global footprint and logistics advantages

In today's competitive automotive landscape, short transportation distances can bring significant advantages in terms of efficiency, cost-effectiveness, and environmental impact. Contract manufacturers with manufacturing sites in automotive clusters, such as those in Eastern Europe, are well-positioned to optimize logistics and supply chain management, delivering components to Tier 1/2 suppliers faster and at a lower cost.

By carefully evaluating these critical factors, automotive Tier 1or 2 suppliers can identify and partner with contract manufacturers who possess the expertise, agility, and commitment to excellence that are essential for navigating the e-mobility revolution and meeting the evolving needs of their customers.

In this example, you can find out more about how collaboration between a Tier 2 manufacturer and its supplier worked very well for solenoid valves.