Which factors determine the choice of core material for micro coils?

When it comes to choosing the core material for your micro coil, it's essential to carefully evaluate the advantages and disadvantages while considering the specific requirements. So, what factors should you take into account when selecting the core material for your micro coils?

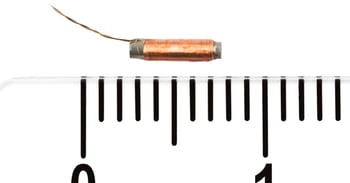

Selecting the appropriate core material is a crucial step in the manufacturing of micro coils. Different materials possess unique properties and are suitable for various applications. Therefore, it is essential to carefully choose the right material in order to achieve the desired results.

Key considerations in core material selection

-

Permeability: The permeability of the core material plays a crucial role in enhancing the coil's ability to amplify magnetic fields. Amorphous and nanocrystalline materials often exhibit high permeability values, making them well-suited for applications that require strong magnetic fields.

-

Losses: Another critical factor to consider is material losses. Amorphous and nanocrystalline materials are often characterized by low losses, making them particularly suitable for high-frequency applications and improving energy efficiency.

-

Temperature stability: The temperature stability of the core material is important to ensure reliable functioning of the micro coil in various environments. Neodymium core materials are renowned for their excellent temperature stability.

-

Size and shape: The size and shape of the core material influence the overall size of the micro coil. It is essential to choose a material that aligns with the spatial requirements of the application. Neodymium magnets are well-known for their compact size.

Availability and cost

In addition to technical requirements, considering the availability and cost of the core material is crucial. Neodymium core materials can increase overall manufacturing costs due to their rarity and high prices.

Neodymium is a rare earth metal that occurs in low concentrations in the Earth's crust. The largest deposits of neodymium are found in China, Australia, the CIS countries, and Brazil. Neodymium is typically extracted from ores that also contain other rare earth metals. The extraction of neodymium is an energy-intensive process that can lead to significant environmental impact.

Conclusion on selecting the optimal core material

Choosing the right core material for micro coils is a crucial step in achieving the desired performance goals. It is important to carefully consider the factors mentioned above and make the material selection based on the specific requirements of your application. Amorphous, nanocrystalline, and neodymium core materials can be excellent choices depending on the application, and their individual advantages and disadvantages should be taken into account when making decisions.

Choosing the right core material for micro coils is a crucial step in achieving the desired performance goals. It is important to carefully consider the factors mentioned above and make the material selection based on the specific requirements of your application. Amorphous, nanocrystalline, and neodymium core materials can be excellent choices depending on the application, and their individual advantages and disadvantages should be taken into account when making decisions.