Defence

HIGH-RELIABILITY COILS FOR DEFENCE APPLICATIONS

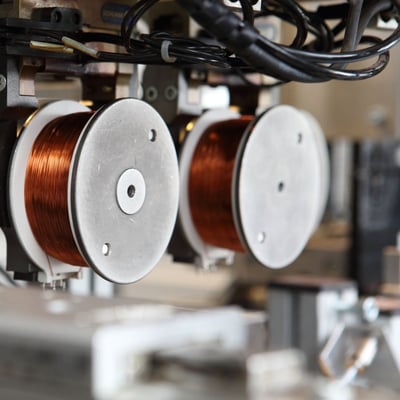

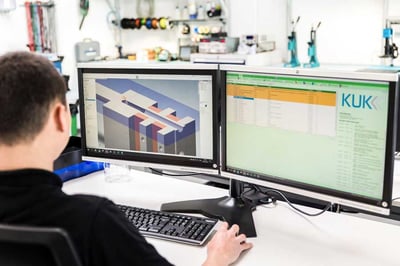

KUK Coils is a trusted production partner for defence industry applications, providing high-reliability electromagnetic components that meet the demanding requirements of military and defence systems. Our manufacturing expertise includes precision winding techniques and rigorous quality control processes that ensure optimal performance in the most challenging operational environments.

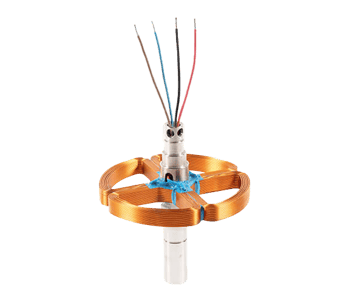

PRECISION WINDINGS FOR UAV MOTOR

Project:

Coils for high-performance Unmanned Aerial Vehicles (UAV) motors

Know-how:

Enabling UAV motors to achieve peak power within stringent weight limitations

Advantage:

Reliable motor components, from specialized windings and stators to integrated motor solutions, ensuring seamless functionality and robust performance

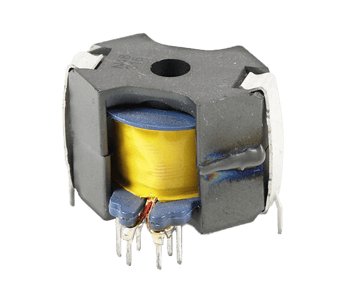

MINIATURIZED COILS FOR DEFENCE ELECTRONICS

Project:

Ultra-compact coils for tactical communication devices

Know-how:

Precision winding with ultra-thin wire and specialized core materials

Advantage:

Space and weight reduction without compromising performance, enabling more compact and portable defence systems

KUK specializes in the development and production of lightweight aluminum and Copper Clad Aluminum (CCA) coils that address the critical weight constraints of modern defence systems without compromising electrical performance. Our manufacturing expertise includes precision winding with aluminum and CCA wires that deliver optimal conductivity-to-weight ratios, enhanced with specialized insulation and protection methods that ensure reliability in demanding military environments.

COILS FOR WEIGHT-SENSITIVE APPLICATION

Project:

Aluminum and CCA wire coils for airborne reconnaissance systems

Know-how:

Specialized winding techniques for aluminum and copper-clad aluminum wire

Advantage:

Up to 70% weight reduction compared to pure copper coils, enabling extended mission duration and improved payload capacity for aerial defense platforms

ELECTROMAGNETIC SHIELDING SOLUTIONS

KUK provides comprehensive electromagnetic shielding solutions that protect sensitive defence electronics from interference in complex electromagnetic environments. Shielding solutions help maintain secure communications, protect sensitive data, and ensure reliable operation of critical systems even in environments with significant electromagnetic noise or deliberate jamming attempts.

COIL WINDING AND ASSEMBLY SERVICES FOR DEFENCE

Air core coil cylindrical/rectangular

KUK manufactures cylindrical or rectangular air core coils according to your unique specifications. Special wire, such as flat wire, or even orthocyclic windings are used.

Windings on customer-specific bobbins

KUK offers windings on customer-specific coil formers with all common bobbin shapes and geometries. All conceivable shapes of electric coils are customer-specific manufactured.

Transformers

For many years, KUK Group has been a leading manufacturer of customer-specific transformers, chokes and transmitters - both for high frequency (HF) and low frequency (LF).

Assembly of complete modules

In addition to the high level of competence in coil production, customers also value potting and assembly to stators or complete motors.

READY WITH A NEW PROJECT?

Our experts for coil and electronics manufacturing will be pleased to advise you.