Supply chain options for defence coil winding

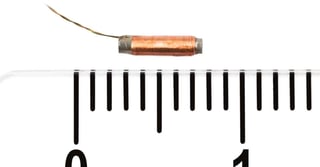

In the face of evolving global strategic demands, the defence sector is experiencing a shortage in coil winding capacity. Learn how partnering with established contract manufacturers can bridge this gap and ensure mission-critical reliability. Opting for partners with established Western supply chains and production sites provides defence contractors with confidence in the reliability, ...