Advanced Engineering Antwerp

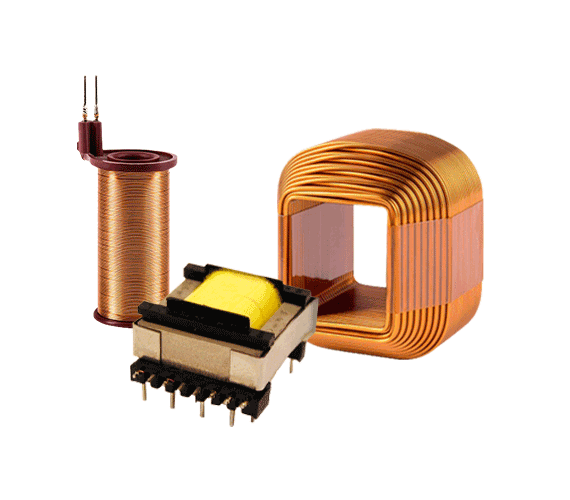

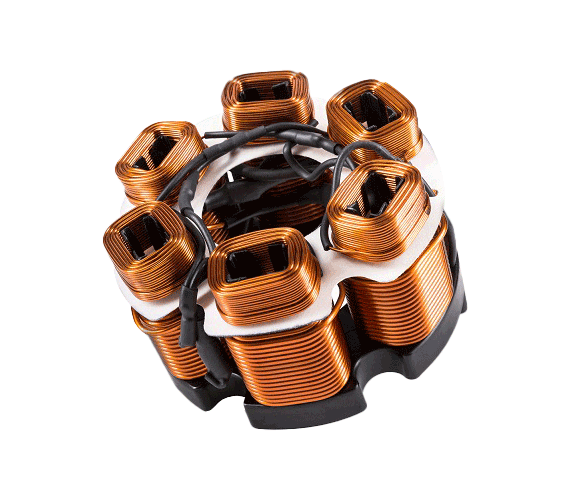

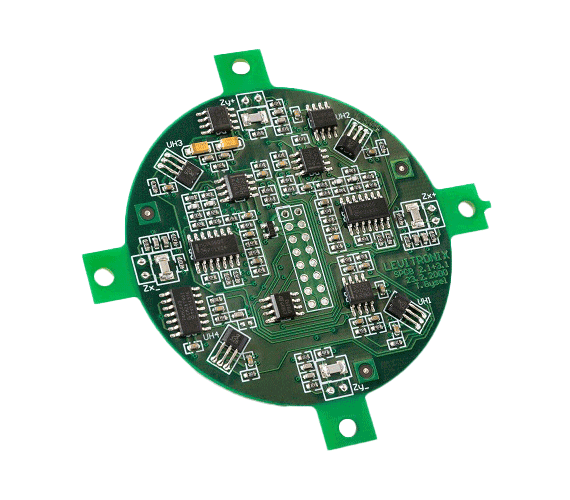

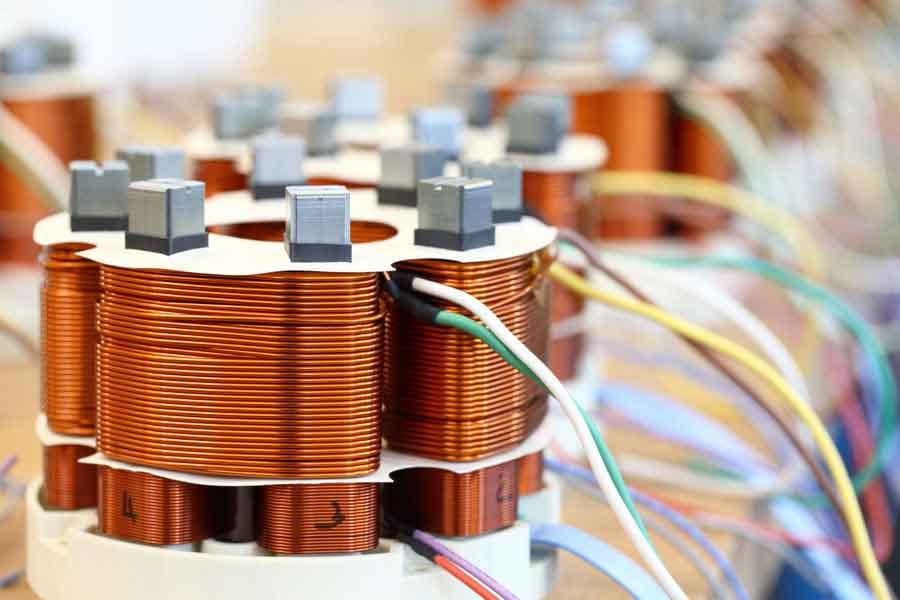

Customer-specific winding goods and EMS

SUCCESSES OF OUR CLIENTS

«The combination of linear drive and pipette in the MagPip, an innovative pipetting channel, is new and permits unparalleled piston acceleration.»

Jury statement German Innovation Award

OUR KNOW-HOW AND SERVICES

FEASIBILITY

.png?upsize=true&upscale=true&width=72&height=72&name=settings(1).png)

OPTIMIZATION

SAMPLING

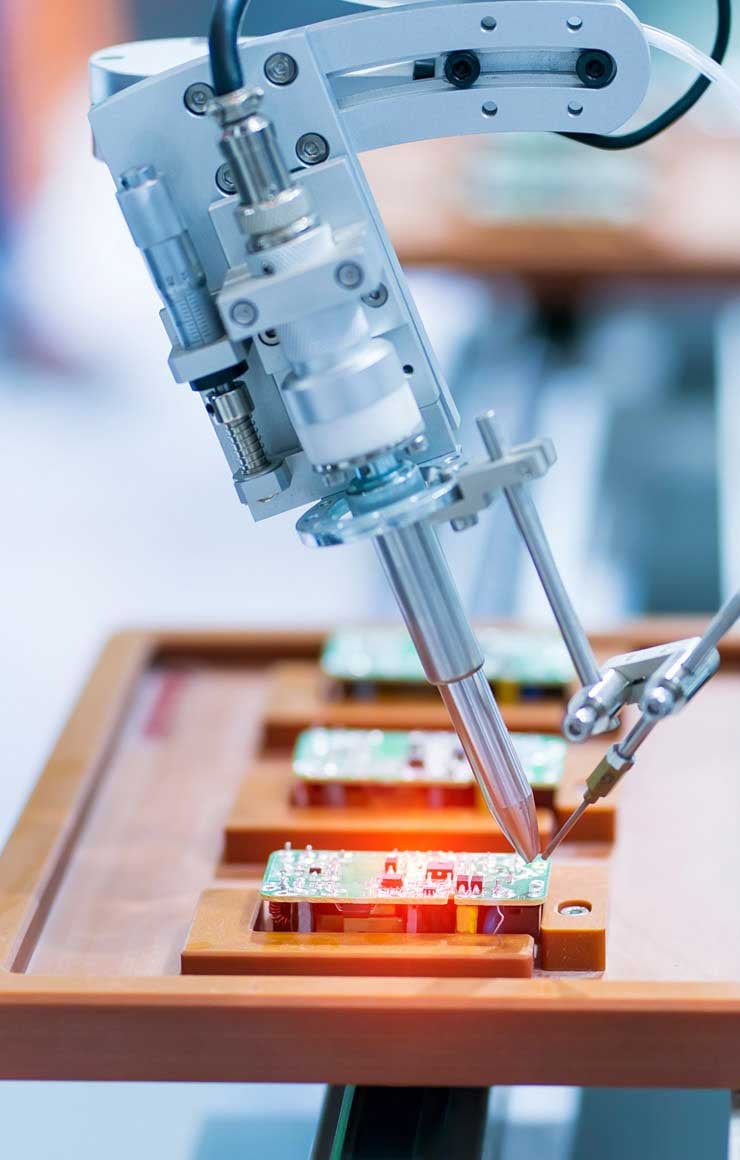

AUTOMATION

SERIES

SCALING

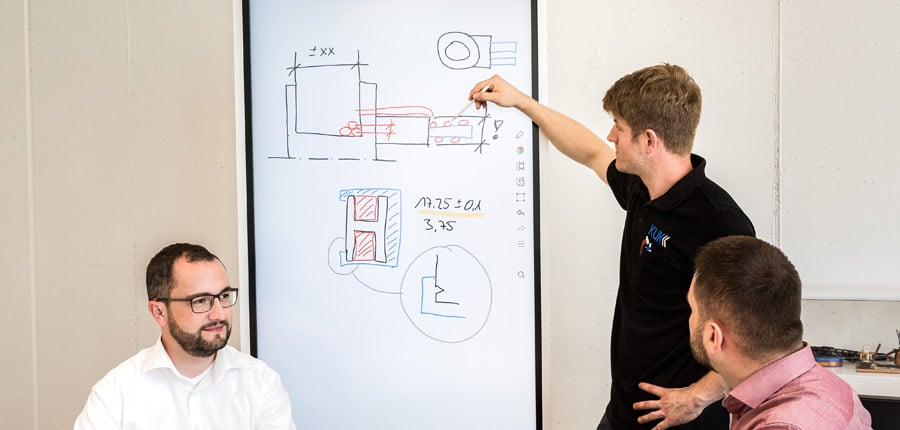

Process partner from product idea to large-scale production

KUK serves the customer according to individual requirements from development phase to the integration of the goods into the global supply chain.

Overview competences

DEVELOPMENT

Already during prototyping, KUK provides important information that turns out to be of great value in series production.

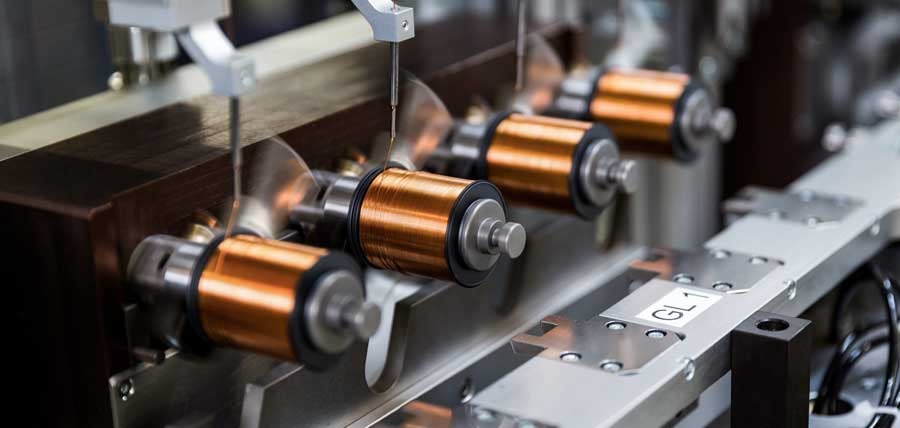

AUTOMATION

KUK's own plant construction guarantees high-quality series production and a short time to market for coil production.

KUK GROUP FACTS & FIGURES

1990

COMPANY FOUNDED IN SWITZERLAND

7

GLOBAL PRODUCTION SITES

1000

EMPLOYEES

90%

MANUFACTURED ON IN-HOUSE BUILT MACHINES

> 200 MIO

WOUND COILS/YEAR

> 1 MIO

MOUNTED MODULES/YEAR

> 1 MIO

ASSEMBLED PCB/YEAR